The supplement process in auto body shops involves a precise, multi-step approach to vehicle restoration, from initial assessments to specialized repair techniques like paintless dent repair (PDR). Skilled technicians use advanced tools and cost-effective alternatives, such as spot welding and plastic fillers, to streamline repairs, reduce material and labor costs, and shorten turnaround times. Digital systems for order tracking and inventory management further optimize the supplement process, enhancing productivity and reducing delays, ultimately benefiting both businesses and customers.

In today’s complex automotive landscape, understanding the supplement process is paramount for managing repair costs and timelines. This article delves into the intricate details of the supplement process, its various components, and their profound impact on vehicle repairs. We explore how optimizing this process can significantly reduce costs and expedite service, providing valuable insights for auto shops and insurance providers alike. By understanding these dynamics, professionals can navigate the supplement process more efficiently.

- Understanding the Supplement Process and Its Components

- The Impact on Repair Costs: What You Need to Know

- Streamlining Timelines: Efficient Supplement Process Practices

Understanding the Supplement Process and Its Components

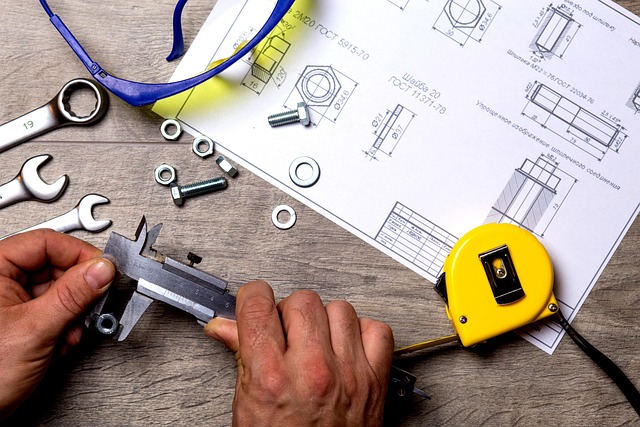

The supplement process in an auto body shop is a complex series of steps designed to enhance and optimize the restoration of damaged vehicles, particularly through techniques like paintless dent repair. It involves several critical components that work together to achieve precise results. One key aspect is the initial assessment, where skilled technicians meticulously examine the vehicle to identify the extent of the damage and determine the most effective repair methods.

This process then delves into specialized procedures tailored to various types of damage, such as dent removal or panel replacement. For instance, paintless dent repair techniques use specialized tools and expertise to remove dents without the need for traditional painting, thereby saving time and costs in automotive collision repair. Understanding these intricate processes is vital for managing repair timelines and keeping costs efficient, ensuring a seamless return to the road for vehicle owners.

The Impact on Repair Costs: What You Need to Know

The supplement process plays a pivotal role in managing repair costs and timelines, especially when it comes to complex auto body repairs like frame straightening or paintless dent repair. By incorporating additional treatments and products during the restoration process, technicians can significantly reduce overall expenses and speed up turnaround times. For instance, advanced techniques such as spot welding or specialized sealants can minimize material costs and labor requirements compared to traditional methods.

Furthermore, understanding how the supplement process interacts with various auto dent repair services is crucial. Paintless dent repair, for example, relies on supplements like plastic fillers and polishes to restore a vehicle’s original finish without extensive frame straightening. This not only saves on expensive paint jobs but also expedites the entire repair process, ensuring customers receive their vehicles back in a timely manner.

Streamlining Timelines: Efficient Supplement Process Practices

The supplement process plays a pivotal role in streamlining timelines for vehicle paint repair and body shop services. Efficient practices within this process can significantly reduce the time required to complete repairs, thereby enhancing overall productivity. By optimizing the way supplements are ordered, received, and integrated into the workflow, body shops can minimize delays caused by bottlenecks and ensure smoother operations.

One of the key aspects is implementing digital systems that automate order tracking and inventory management. This allows for real-time visibility into supplement availability, enabling faster decision-making and reducing waiting times. Additionally, adopting technologies like paintless dent repair techniques further revolutionizes the supplement process. These innovative methods eliminate the need for extensive repainting, accelerating the repair timeline and contributing to cost savings for both body shops and their customers.

The supplement process plays a pivotal role in managing repair costs and timelines. By understanding its various components, you can optimize each step to minimize expenses and expedite projects. Implementing efficient practices throughout the process ensures that repairs are not only cost-effective but also completed faster, ultimately benefiting both businesses and customers.