The supplement process is vital for auto bodywork repair, encompassing diverse techniques from dent removal to car paint repairs. Both small and large shops can enhance their services through optimized processes. Small shops can streamline operations with efficient inventory management, anticipative ordering, and continuous improvement. Large shops tackle complex restoration with detailed strategies, reliable suppliers, and streamlined ordering, ensuring productivity, quality, and faster turnarounds in a competitive market.

The supplement process is a critical aspect of automotive repairs, ensuring parts and labor costs are accurately accounted for. This article provides essential insights for both small and large repair shops looking to optimize their supplementing strategies. We explore ‘Understanding the Supplement Process’ as the cornerstone for all shops, followed by dedicated guides: best practices for small shops and comprehensive strategies for large-scale operations. Unlock efficient billing, enhanced profitability, and improved customer satisfaction with these valuable tips on mastering the supplement process.

- Understanding the Supplement Process: A Foundation for All Shops

- Best Practices for Small Repair Shops to Optimize Supplementing

- Implementing Supplement Strategies for Large-Scale Operations: A Comprehensive Guide

Understanding the Supplement Process: A Foundation for All Shops

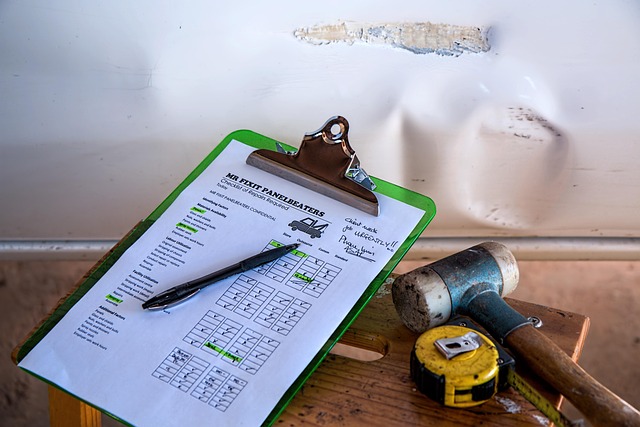

The supplement process is a crucial aspect of auto bodywork and repair, encompassing various techniques to enhance and restore vehicle aesthetics. For both small and large repair shops, understanding this process serves as a foundational step in delivering high-quality services. It involves a series of meticulous procedures tailored to specific damage, whether it’s a minor dent removal or intricate car paint repair.

By familiarizing themselves with the supplement process, repair shop professionals can effectively assess and address different types of auto bodywork issues. This knowledge enables them to choose the right tools, materials, and methods for each unique case, ensuring efficient and precise results. Whether focusing on dent removal or handling complex paint jobs, a solid grasp of this process allows shops to offer comprehensive solutions, thereby fostering customer satisfaction and building a positive reputation in the competitive automotive industry.

Best Practices for Small Repair Shops to Optimize Supplementing

Small repair shops can optimize their supplement process by implementing several best practices tailored to their size and scope. Firstly, they should invest in efficient inventory management systems to track parts and supplies accurately, minimizing waste and ensuring quick access during busy periods. This involves digitizing records, setting up automated reorders for frequently used items like car scratch repair kits, and establishing partnerships with reliable suppliers for timely deliveries, especially for collision repair components.

Additionally, training staff in effective supplementing techniques can significantly enhance productivity. This includes teaching them to anticipate parts needs based on recurring repairs, such as common car damage repair issues, and pre-packing kits for quick service. By fostering a culture of continuous improvement and encouraging feedback from technicians, small shops can streamline their processes further, making the most of every resource while delivering high-quality collision repair services.

Implementing Supplement Strategies for Large-Scale Operations: A Comprehensive Guide

For large-scale auto repair shops handling complex vehicle restoration or car paint repair jobs, implementing strategic supplement processes is a game-changer. These operations often involve intricate tasks that demand specialized materials and techniques. A well-defined supplement strategy ensures that the right components and resources are readily available, streamlining work flows and minimizing delays.

Comprehensive guidance involves mapping out specific needs for each project phase—from initial assessment to final touch-ups. This includes identifying potential gaps in in-house inventory, researching reliable suppliers, and establishing efficient ordering protocols. By adopting these strategies, large repair shops can enhance productivity, maintain high-quality standards, and ultimately provide faster turnaround times for their clients, fostering customer satisfaction and loyalty in the competitive auto repair market.

The supplement process is a vital aspect of automotive repair, catering to both small and large shops with unique requirements. By understanding and implementing best practices, regardless of size, workshops can enhance efficiency, reduce costs, and improve customer satisfaction. For small repair shops, optimization strategies focus on streamlining procedures and leveraging technology, while larger operations benefit from comprehensive guidelines ensuring consistent quality across diverse departments. Embracing these tips equips technicians with the tools to navigate the supplement process successfully, fostering growth and excellence in their respective automotive care niches.